Wintek Operating System

The chamber's conditions must be carefully controlled during the process. For this reason, the chamber is equipped with a wide range of sensor technology to maintain optimal conditions.

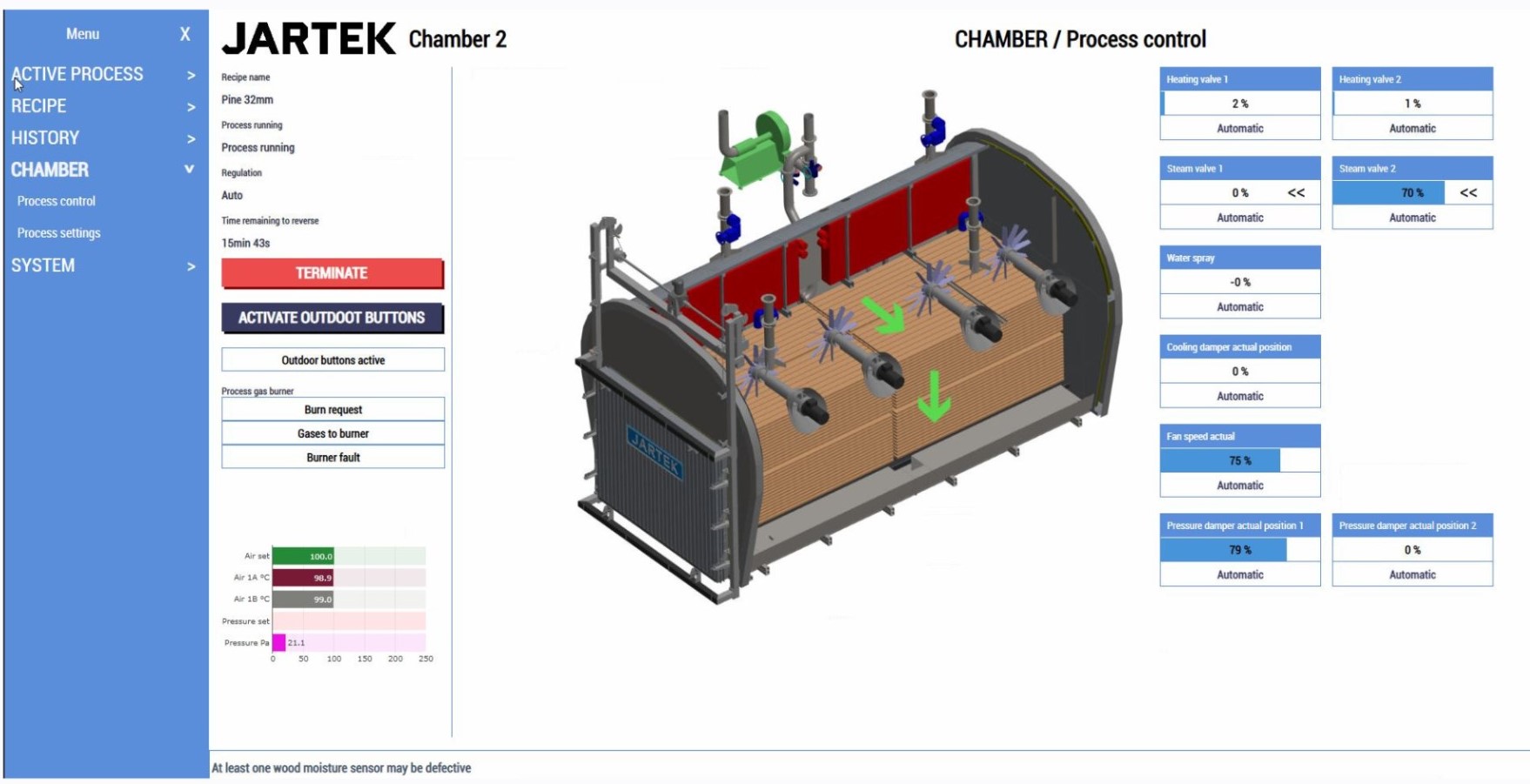

The process is controlled by Jartek's own Wintek software. Each wood species has its own tailor-made program, and as the process progresses, automation ensures that it is carried out as desired. The Wintek software stores history data on all processes, allowing for process comparison and optimization. Siemens logic is at the heart of the Wintek software. The recipes used in the thermal modification process are open and can be freely modified and optimized by the customer.

Modernisation of old thermal modification chambers

We modernize old thermal modification chambers as needed to meet the requirements of the ThermoWood® brand. We update outdated and time-worn thermal modification chambers with modern technology and contemporary automation, regardless of the original supplier. If you're looking for ways to modernize and enhance your thermal modification processes, we can help you find the best possible solution.

Benefits:

- Better quality. The quality of the modified wood is consistent, and the process is controllable

- Ease of use. The new control system is user-friendly and informative

- Environmentally friendly. The ThermoWood® process is an ecologically sustainable choice.

- A controlled process

- Visual layout